OUR SERVICES

Quality Control

Our company implements the ISO 9001:2015 Quality Management System. Furthermore, the necessary infrastructure and documentation for the AS 9100 Aviation Quality Management System have been established, and the system is operational. The AS 9100 certification process will be completed shortly.

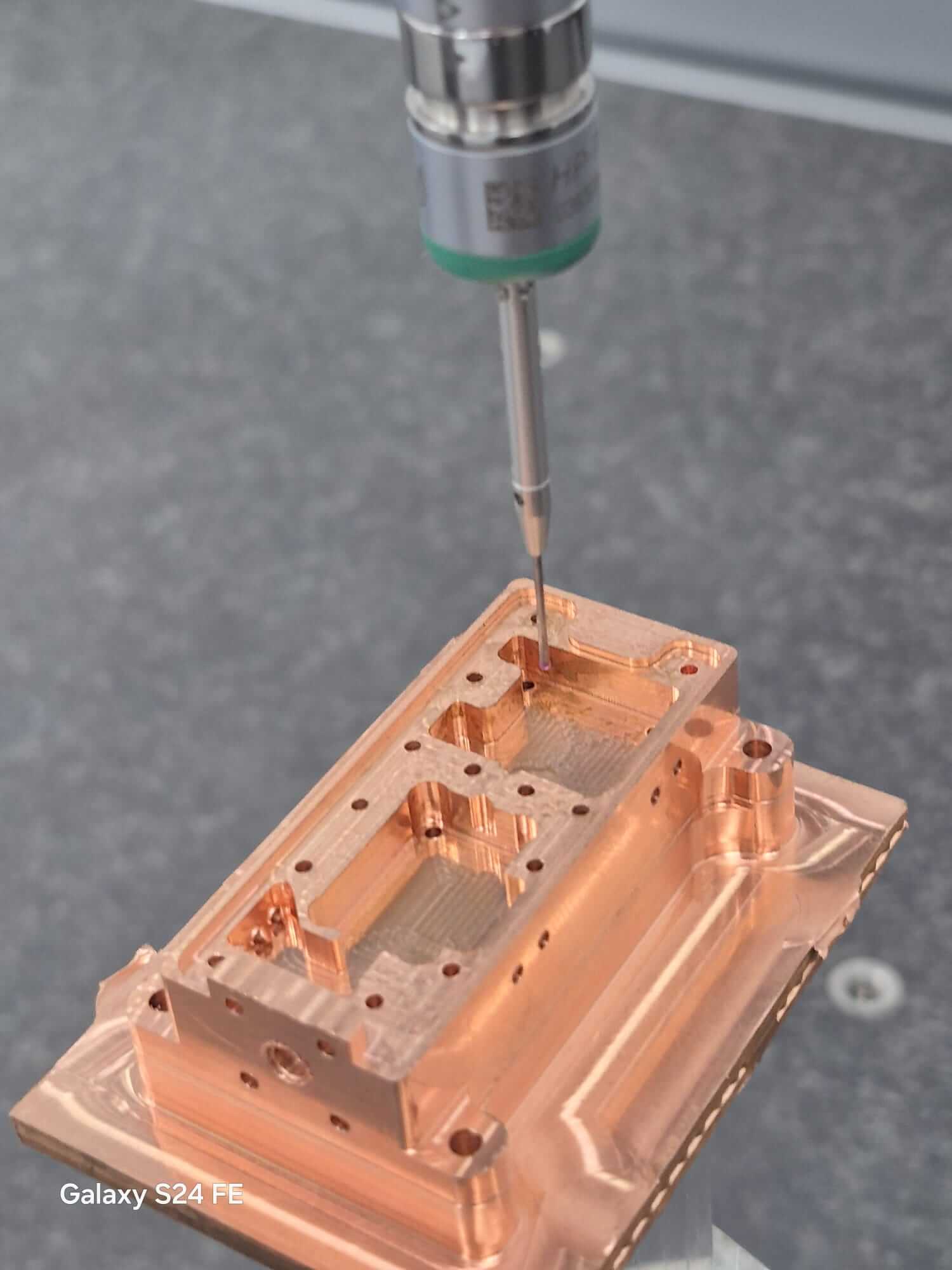

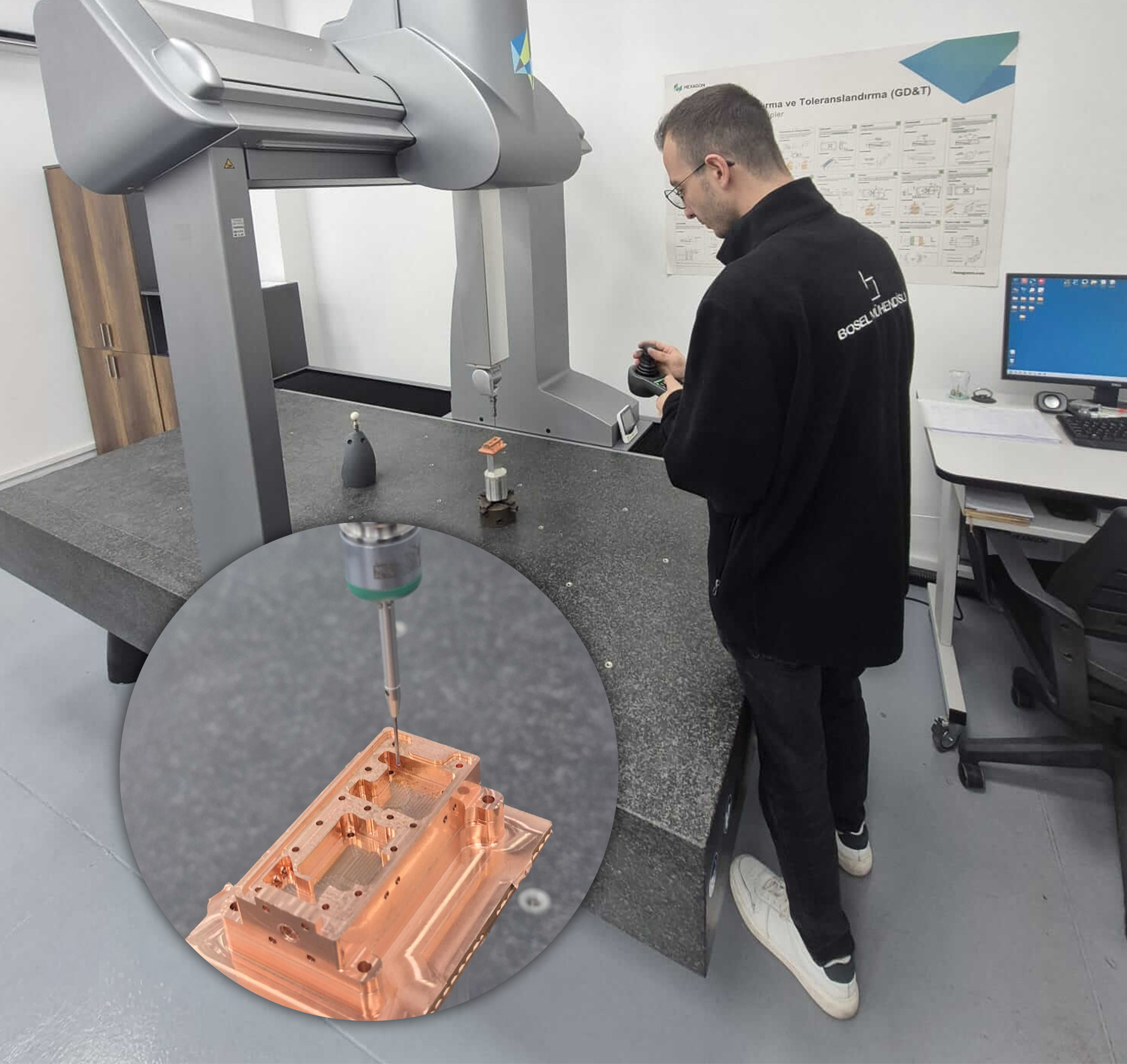

Quality control activities are carried out using precision measuring equipment, primarily CMM Coordinate Measuring Devices, and each product is meticulously inspected for compliance with specifications.

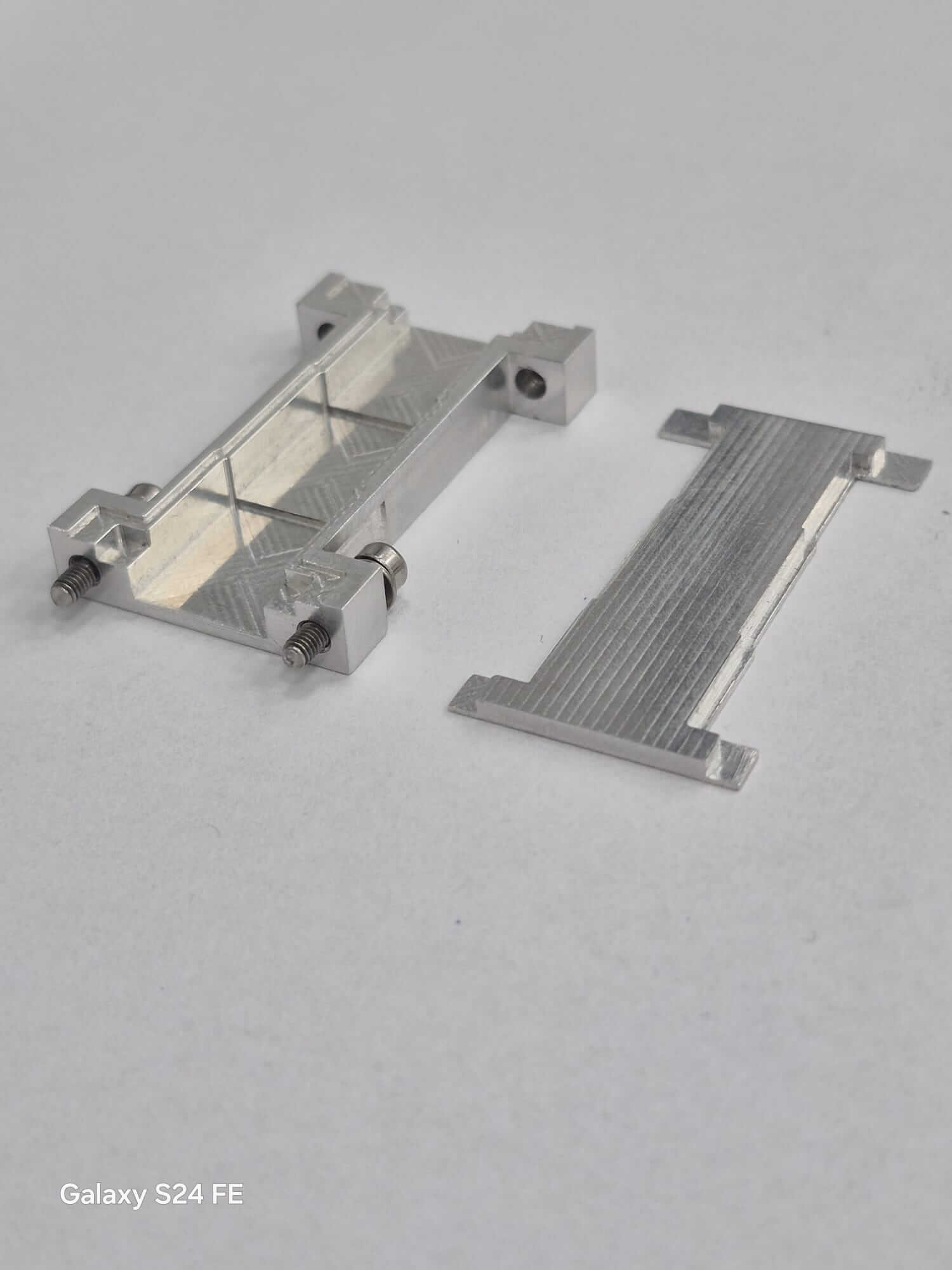

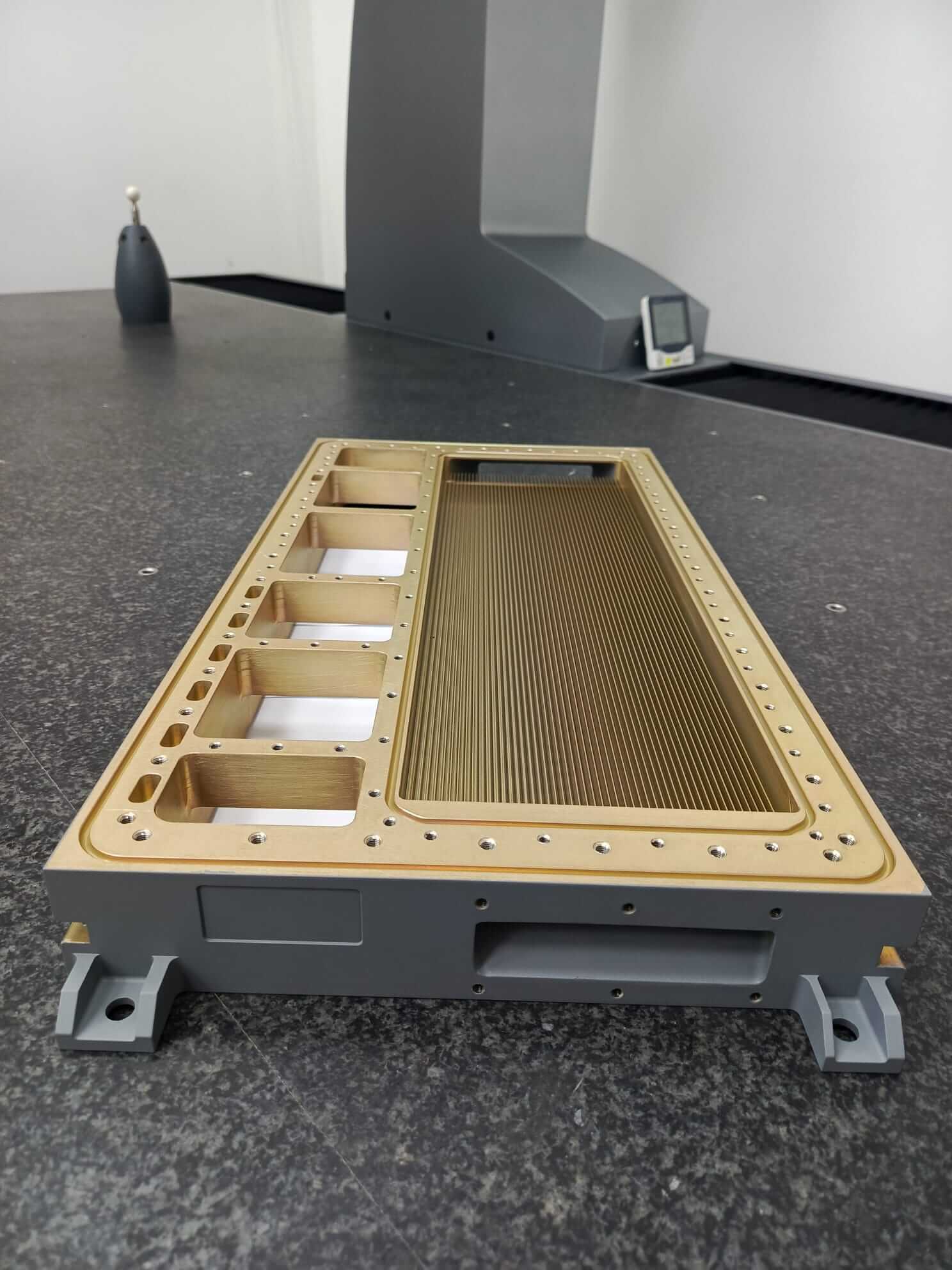

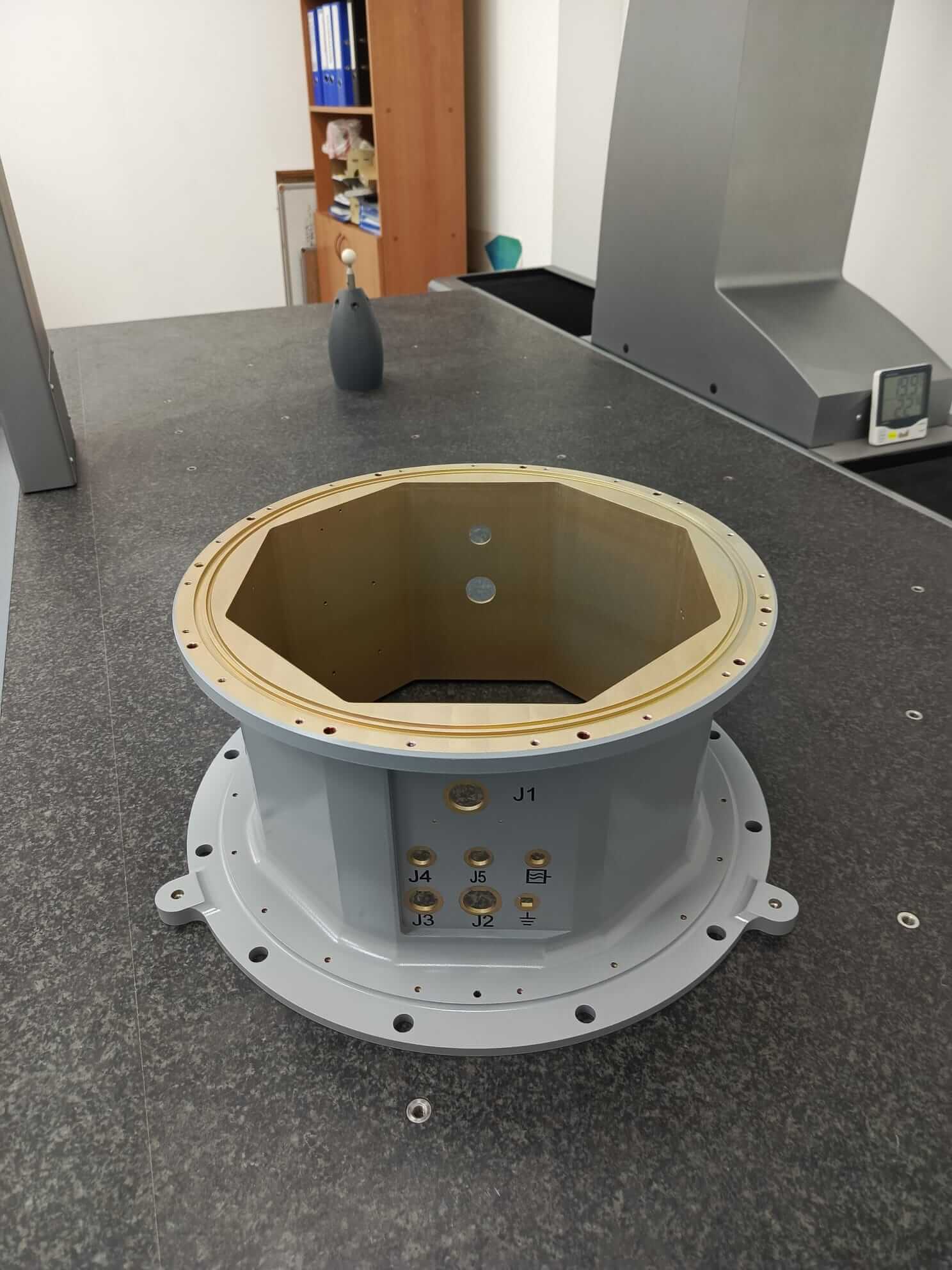

Dip Brazing

Aluminum Brazing, also known as aluminum brazing, is a brazing technology that joins aluminum parts that cannot be produced by machining using various chemicals at high temperatures. This method is particularly useful for manufacturing many cooled electronic chassis, antenna components, and various other components.

Dip Brazing Advantages

• Production of complex multi-component systems.

• Easy production of large-area or long connections.

• Joining thin aluminum sheets that cannot be joined by TIG welding.

• Joining parts that cannot be produced as a single piece by machining into products.

• Joining materials that can only be produced by casting with precise manufacturing tolerances.

• Preserving the metallurgical properties of metals.

• Achieving precise manufacturing tolerances.

• Producing leak-proof and EMI-protected connections.

CNC Machining

The production of parts requiring high precision is carried out on modern CNC machines, and quality-oriented solutions that add value to our business partners are offered.

Assembly Services

Sub- and main assemblies of the produced parts, Helicoil applications, riveted chassis assemblies, sealing and pressure tests are carried out professionally within our company.

BOSEL ENGINEERING

Being the only company in its field in Turkey, BOSEL Engineering provides high quality Aluminium Dip Brazing services in accordance with customer needs and standards.